Prouducts

CONTACT US

ADDRESS:

No. 439 Jinglian Road, Minhang District, Shanghai,China, 201108

PHONE:+86 21 51096910

EMAIL:

info@welsotech.com

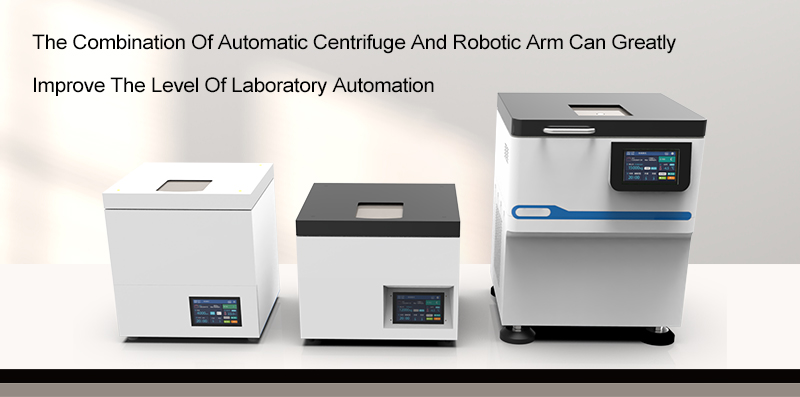

Automated Centrifuge

Product Details

Welso's automated centrifuge is designed for integration into laboratory automation lines. It has the function of automatic loading and unloading through a robotic arm and uses an integrated serial interface for efficient control.

The equipment can automatically perform the operation of picking up and placing centrifuge bottles and opening and closing doors without manual intervention.

The system has a precise positioning function to ensure the safety and accuracy of the centrifuge bottles during operation, thereby improving the automation and safety of the operation.

This automated centrifuge is controlled by a single-chip microcomputer, supports MODBUS communication and 485 output, and is equipped with an intelligent touch-operated display screen, which combines display and operation functions.

It can be controlled by a single machine or by multiple machines. Its rotor load and precise positioning adopt a separate dual-drive system, which breaks through the limitations of servo motors in high-speed load operation, realizes the smooth and stable low-speed operation and the extended function of high speed, and widely meets the different speed requirements of various application scenarios.

Product features:

▼The dual drive system overcomes the problem of the servo motor's speed drop under load conditions.

▼Equipped with a seven-inch large screen display and touch-screen control, it supports arbitrary switching with the host computer control.

▼Equipped with a fully automatic hidden sliding door, the size can be customized, driven by a worm motor, and has strong self-locking ability.

▼The hanging basket design is matched with the automatic door, with a 15mm grab avoidance on one side, and has horizontal and vertical limit functions.

▼The inner cavity and all movable joints are made of 304 stainless steel, which is rust-proof and corrosion-resistant.

▼The rotor is made of 7 series aviation aluminum alloy, which has been hard anodized and has high strength and corrosion resistance.

▼The position calibration origin detection adopts laser non-contact sensing technology to accurately read the position information.

▼Open RS485 communication port and support MODBUS communication protocol.

▼Reserve USB communication port for convenient optimization and upgrade services.

Technical Specifications

Model | WAC1200 | WAC1201 | WAC600 | WAC601 | WAC1500 | WAC1501 |

Max Speed | 12000 | 6000 | 15000 | |||

Max RCF | 15294 | 3823 | 24500 | |||

Max Capacity | 12*10mL (special for small capacity angle rotor) | 4*750mL (can be customized below 750ml, optional) | 4 stations, 16 standard plates (suitable for deep-well plates) | |||

Max speed Rotor capacity | 12*10mL angle rotor | 12*10mL angle rotor | 6*50mL angle rotor | |||

Packing Size | 420*420*535 | 420*420*535 | 470*480*535 | 550*570*585 | 590*640*750 | 590*640*750 |

Net Weight | 40 | 55 | 55 | 82 | 120 | 150 |

Power Consumption | 600 | 800 | 800 | 1000 | 1600 | 1800 |

Temperature | Room temperature +10℃ | -9 to 40°C | Room temperature +10℃ | -9 to 40°C | Room temperature +10℃ | -9 to 40°C |

Noise | ≤65dB(A) | |||||

Power Supply | AC220V/50Hz /10A | AC220V/50Hz /20A | ||||

Related recommendations