Wool is a natural fiber that is rich in keratin and also contains a certain amount of fat and minerals. By analyzing the main components of wool and its physical properties, the quality of wool can be better evaluated. However, due to its soft and elastic texture, how to grind it into powder for component analysis becomes a key issue. Let's explore the grinding method and optimization strategy of wool samples.

Purpose of wool grinding experiment:

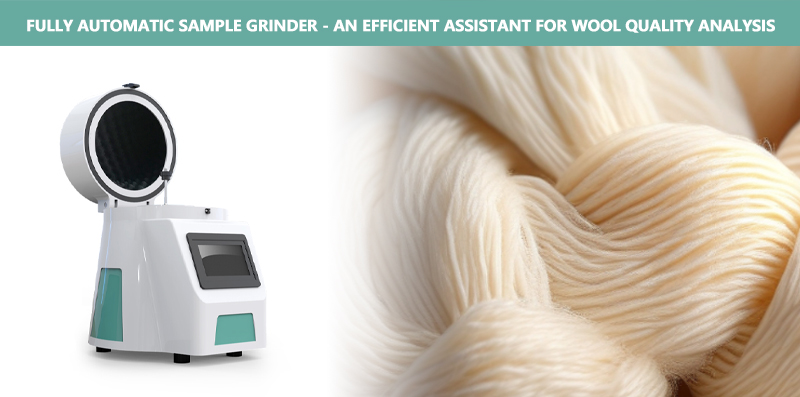

This experiment uses the Welso fully automatic sample grinder to grind wool samples into fine powder and analyze the composition of the obtained wool powder. At the same time, the ground wool powder is mixed with other textile materials and its friction coefficient under different conditions is measured to evaluate the spinnability and textile performance of wool.

Experimental materials and instruments

Materials: wool sample, grinding jar, adapter, grinding beads, liquid nitrogen, etc.

Instrument: fully automatic sample grinder

Reasons for choosing this grinder: This fully automatic sample grinder has many technical advantages, including imported motors, anti-corrosion materials and enhanced motion shafts, which ensure the efficiency and durability of the equipment. Its unique three-dimensional vibration mode can grind, crush, mix and break cells in a short time through the high-speed back and forth collision and friction of the grinding balls in the grinding chamber. Whether it is soil, plant and animal tissues, bacteria, yeast, fungi, spores, or paleontological specimens, they can be thoroughly ground, the grinding effect is uniform and stable, and the operation process is efficient and reliable. These characteristics make it an ideal choice for wool sample grinding and subsequent component analysis.

Experimental steps

Sample weighing and packaging

Weigh 10g of wool sample, divide it into two parts, and put them into two grinding jars respectively.

Cryogenic pretreatment

Place the grinding jar containing the sample in liquid nitrogen to fully freeze the sample to prevent the heat generated during the grinding process.

Loading the grinding jar

Take out the grinding jar from the liquid nitrogen, quickly put it into the adapter, and fix the adapter in the fully automatic sample grinder.

Parameter setting and grinding

According to the characteristics of the sample, set the appropriate grinding parameters (such as grinding time, frequency, etc.), and start the grinder to grind the sample.

Sample removal and analysis

After grinding, take out the sample in the grinding jar to ensure that the sample is evenly refined, and then proceed to subsequent component analysis.

Comparison of experimental results:

By using the Welso fully automatic sample grinder, the wool powder after grinding is fine and uniform, which fully meets the requirements of subsequent component analysis. Customers can safely mix it with other textile materials to ensure that the friction coefficient is measured after the mixture is uniform. The measurement results obtained in this way are more reliable and help to more accurately evaluate the spinnability and textile performance of wool.