The main components of silicate ceramics include silicon oxide and aluminum oxide, and also contain small amounts of impurities such as sodium oxide, potassium oxide, calcium oxide, magnesium oxide, iron oxide and titanium oxide. Among them, titanium may have adverse effects on health because it is ingested by human after dissolution. Therefore, it is particularly important to quickly and accurately detect titanium in ceramic products and their raw materials. The following introduces an efficient microwave digestion method specifically for silicate ceramic products and ceramic raw materials.

●Sample: silicate ceramic powder, grind the ceramic sample into fine powder (recommended particle size <74 μm), and mix thoroughly to improve sample homogeneity.

●Reagent: nitric acid (AR), hydrofluoric acid (AR)

●Instrument : WMD800 intelligent closed microwave digestion instrument

●Sample quantity: 2

Operation procedure:

● Accurately weigh 0.15 g sample (2 portions) to the mg level and carefully place it at the bottom of the digestion inner vessel to ensure that no suspension on the wall.

● Add 2 mL nitric acid and 6 mL hydrofluoric acid respectively, and gently shake the inner vessel to mix the sample and digestion reagent thoroughly to avoid excessive local reaction.

● After the reaction between the sample and the reagent gradually stabilizes, seal the inner tank, load it into the microwave digestion instrument, and perform digestion according to the set program.

The digestion procedure is as follows:

| Pressure(0.1MPa) | 5 | 15 | 25 |

| temperature(℃) | 120 | 180 | 200 |

| power(W) | 3000 | 3000 | 3000 |

| Heating time(S) | 300 | 200 | 120 |

| Constant temperature time(S) | 60 | 120 | 1200 |

●After digestion is completed, cool down the vessels and carefully transfer the digestion vessels to the fume hood and wait for 10 minutes to ensure safety.

●Slowly release the pressure in multiple times, open the digestion tank, take out the inner tank and open it, place the inner vessel in the pretreatment equipment or heating blocks and wait for the solution to almost dry.

●Transfer the remaining solution to a volumetric flask, and rinse the inner vessel and the inner cavity of the sealing cover with an appropriate amount of deionized water to ensure complete recovery of the sample.

●After the digestion solution cools to room temperature, dilute to the volumetric flask graduation with deionized water and wait for testing.

Sample digestion Performance:

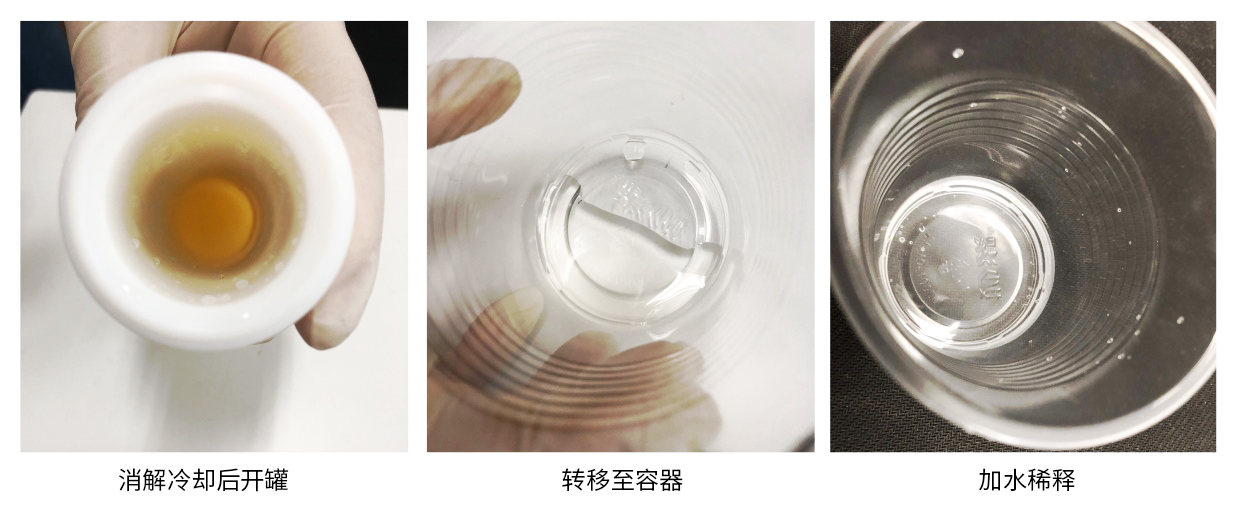

The sample digestion solution is clear and transparent, without precipitation, and the digestion effect is good.

The pictures are shown below:

Experimental Notess:

Wear acid-proof gloves and goggles during operation to prevent acid from contacting the skin.

Operate strictly according to the instruction manual of the microwave digestion instrument.

Microwave digestion technology provides an efficient, fast and reliable solution for sample pretreatment of silicate ceramics and their raw materials, and is particularly suitable for the decomposition and homogenization of complex matrix samples.

By using microwave energy to accelerate the chemical reaction between acidic reagents and samples under high temperature and high pressure conditions, microwave digestion not only significantly shortens the processing time, but also effectively improves the thoroughness of sample decomposition, providing a good foundation for subsequent quantitative analysis. This technology has following advantages:

●Strong sample processing consistency: The uniformity and controllability of microwave heating avoid the problems of local overheating or incomplete digestion in traditional wet digestion, ensuring the accuracy of analysis results.

●High efficiency and energy saving: Compared with traditional heating methods, microwave digestion can significantly shorten the operation time and reduce the use of reagents, helping to reduce costs and reduce environmental pollution.

●High safety: Modern microwave digestion equipment is equipped with multiple safety protection functions, including explosion-proof design, pressure monitoring and automatic pressure relief devices, to effectively prevent possible risks during high-pressure digestion.

●Wide range of application: This technology can process different types of silicate ceramic samples, including high-temperature ceramics, engineering ceramics, and trace and trace elements in their raw materials.

In summary, microwave digestion technology provides new technical support for the pretreatment of silicate ceramics and their raw materials, can meet the current needs for rapid detection and high sensitivity, and has broad application prospects in the field of analysis.