The pore size of the membrane

Pore size 0.45 μm membrane: used for routine sample mobile phase filtration, which can meet general chromatographic requirements.

0.22 μm pore size membrane: It can remove very fine particles from samples and mobile phases, as well as remove microorganisms.

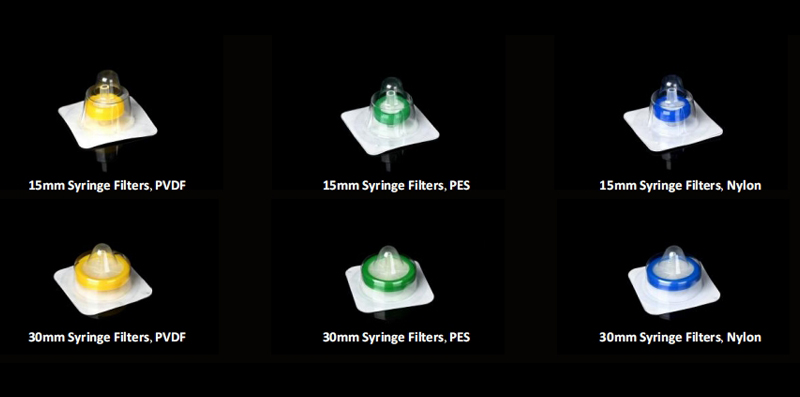

The diameter of the membrane

There are two commonly used filter diameters: Φ13μm and Φ25μm

Φ13μm is suitable for sample volume from 0 to 10 mL

Φ25μm is suitable for sample volume of 10-100mL

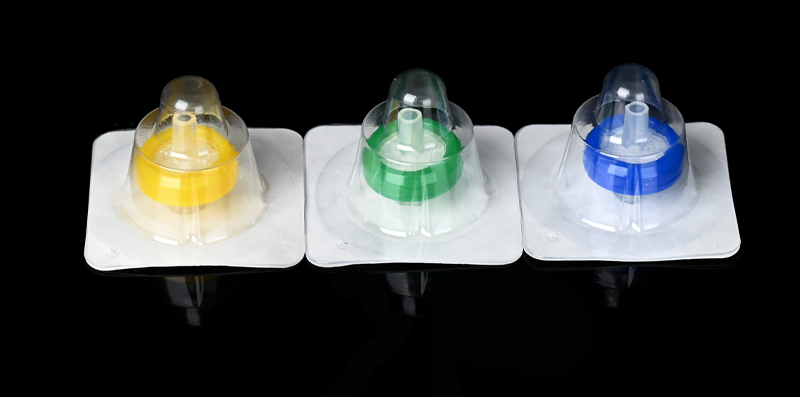

Commonly Used Membrane Material

●Nylon

Features: Good temperature resistance, can withstand 121 °C steam hot pressure disinfection for 30min, good chemical stability, can withstand dilute acids, dilute alkalis, alcohols, esters, oils, hydrocarbons, halogenated hydrocarbons and organic oxides and other organic and inorganic compounds.

Application: Filtration of aqueous solutions and organic mobile phases.

●PVDF

Features: The membrane has high mechanical strength, good heat resistance and chemical stability, and low protein attachment; It has strong negative electrostatic and hydrophobicity; However, it cannot tolerate acetone, dichloromethane, chloroform, DMSO, etc.

Application: Hydrophobic PVDF membrane is mainly used in gas and steam filtration, and high-temperature liquid filtration. Hydrophilic PVDF membranes are mainly used in the aseptic treatment of tissue culture media and solutions, high-temperature liquid filtration, etc.

●PES

Features: Hydrophilic membrane, with high flow rate, low extractables, good strength, no adsorption of proteins and extracts, no pollution to the sample.

Applications: Designed for biochemical, assay, pharmaceutical, and sterilization filtration.

●MCE

Features: uniform pore size, high porosity, no medium shedding, thin texture, low resistance, fast filtration rate, minimal adsorption, low price and cost, but not resistant to organic solutions and strong acids and alkali solutions.

Application: Filtration of aqueous solutions or sterilization of heat-sensitive preparations.

●PTFE

Features: Widest chemical compatibility, resistant to organic solvents such as DMSO, THF, DMF, dichloromethane, chloroform, etc.

Application: Filtration of all organic solutions and strong acids and bases, especially strong solvents that cannot be tolerated by other filter membranes.

According to the specific experimental needs, we can accurately select the syringe filter.

Select the appropriate membrane

A: Hydrophilic sample: Hydrophilic diaphragm is suitable for selection, and the available filter membranes are aqueous membrane (MCE) and nylon membrane (Nylon).

B: Organic and inorganic compounds (alcohols, esters, oils) samples: Nylon membranes are selected.

C: Protein solution sample: suitable for low protein adsorption filter membrane, i.e., PVDF membrane.

D: Strong organic solvent sample: suitable for hydrophobic PTFE.

E: Ion chromatography: It is generally considered that PES filter membrane is more suitable for the filtration of solutions with low inorganic ions.

Hope you have deep understanding of syringe filters through above information. If you need syringe filters, please feel free to contact us.