The application of centrifugation technology has been very mature and centrifuges have become necessary in biochemical laboratory laboratories. With the rapid development of the field of biotechnology, the automatic biochemical molecular detection workstation has begun to gradually promote to replace the original manual work.

Intelligent testing workstation, manual only need to complete the simple steps of sample loading, greatly reducing manual operation. The robotic arm is used to undertake tasks such as sample transfer and distribution, and its error accuracy is only ≤ 0.1mm, which greatly simplifies the personnel operation process and improves work efficiency.

Robotic arms are becoming more and more flexible and intelligent, and they can complete the whole process of experiments completely and analyze them in real time. Its automated, efficient, intelligent and accurate characteristics provide more powerful support for life science research and hospital testing.

The automatic intelligent positioning centrifuge supports automated intelligent workstations, which do sample pretreatment and can communicate with workstation, using robotic arm to complete the whole process of loading, centrifugation, positioning and sampling, and perfectly realize unmanned operation.

Each step of the centrifuge, such as stop, acceleration and deceleration, centrifugation time, lid opening, rotor position, etc., are automatically controlled, which completely frees the hands of the users and makes the experimental results more accurate.

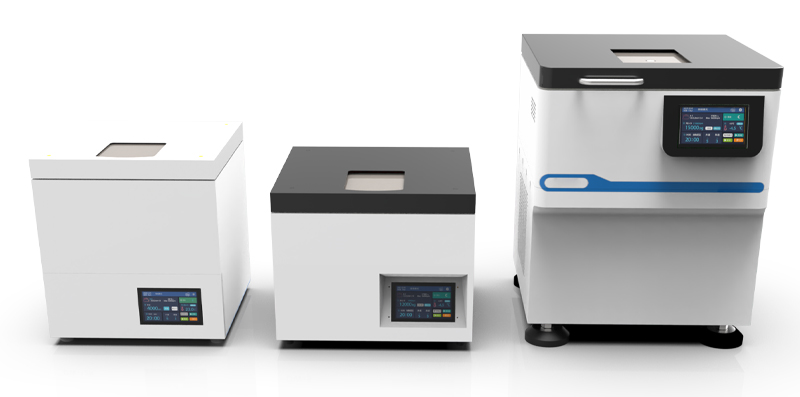

Welso centrifuges meet a wide range of requirements

Welso automatic centrifuge is specially designed for automatic workstation, which can be controlled by a single machine or a multi-machines, with two-in-one display and operation functions, and a dual drive with a separate rotor load and precise positioning, which breaks through the shortcomings of the servo motor that cannot be loaded and operated, and realizes the smooth running of high and low speeds, and better meets the different needs of various application scenarios for speed.

Features

●7’ large screen, touch control, can switch control with the workstation.

●Fully automatic sliding door which can be customized

●Driven by worm motor which has strong self-locking ability

●The hanging blue corresponds to the automatic door, with 15mm on one side to grab and avoid the space, and there are horizontal and vertical limits

● Automatic door with 15mm on one side to grab, and there are horizontal and vertical limits

●The inner cavity and all movable joints are made of 304 stainless steel, which is rust-proof and corrosion-resistant

●The rotor is made of 7 series aviation aluminum alloy, hard anodized treatment, high strength and corrosion resistance

●Position calibration origin detection adopts laser non-contact induction to read position information

●Open RS485 communication port, provide MODBUS communication protocol

●Reserved USB port for further upgrade

With the continuous development and application of high-tech automatic detection station technology in the future, the future prospects of automatic positioning centrifuges will become more and more broad, and the future automated testing station will be more intelligent and automated, covering more fields to bring more benefits and development opportunities to human society.