The microwave digestion instrument uses microwave energy to complete the sample digestion quickly and efficiently, it can reach hundreds of degrees Celsius in a few minutes, and the ability to heat uniformly can make the sample digestion more complete and uniform, improving the accuracy and reliability of the detection.

Microwave digestion has been used in the food industry for a long time, especially in food nutrition analysis, such as the determination of trace elements, minerals and other nutrients in food, which can quickly and accurately do sample preparation.

Digestion of such samples often encounters two problems: first, a large amount of degradation gas is generated, which increases the pressure of the system; Secondly, the organics undergo heating reaction and increases the temperature of the system. In the process of digestion of such samples, the energy release is often instantaneous, the pressure and temperature will rise instantaneously, and the temperature can fall, but the pressure is sometimes difficult to recover, so there may still be some residual pressure in the digestion tank after microwave digestion cooling.

The following describes the microwave digestion method of oat grains, a class of food samples.

Sample name: Oat grains

Chemical reagent: 65% nitric acid AR; 30% hydrogen peroxide AR; hydrochloric acid (6mol/L); potassium ferricyanide solution (100g/L);

Instrument : WMD600

Digestion Procedure is as followed:

| Pressure(0.1MPa) | 10 | 20 | 35 |

| Temperature(℃) | 120 | 165 | 200 |

| Power(W) | 1000 | 1000 | 1000 |

| Heating Time(s) | 300 | 240 | 180 |

| Constant temperature time(s) | 60 | 120 | 600 |

After digestion and cooling, move digestion vessel to fume hood and wait for 10 minutes.

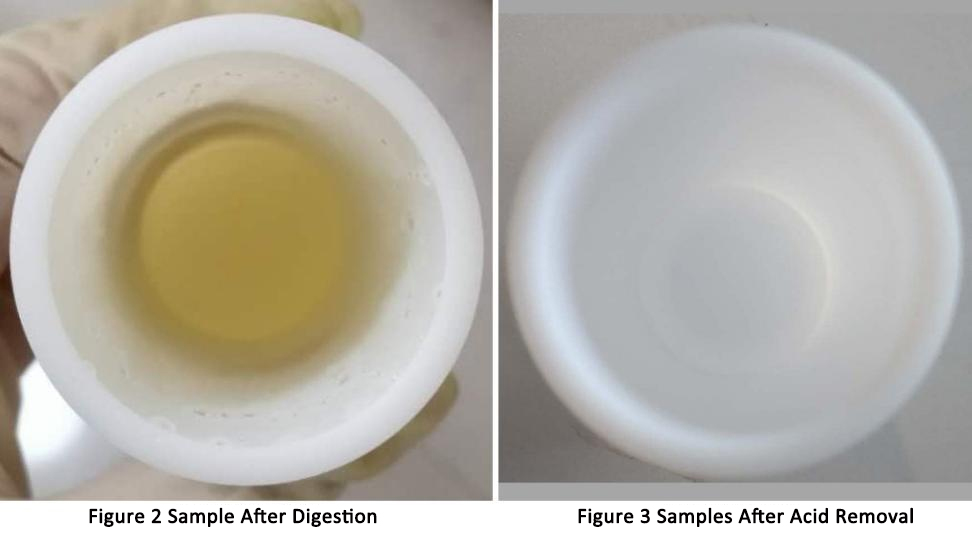

Open the outer vessel: Unscrew the outer vessel and release pressure for several times. Open and take out the inner vessels, Digested samples are as follows:

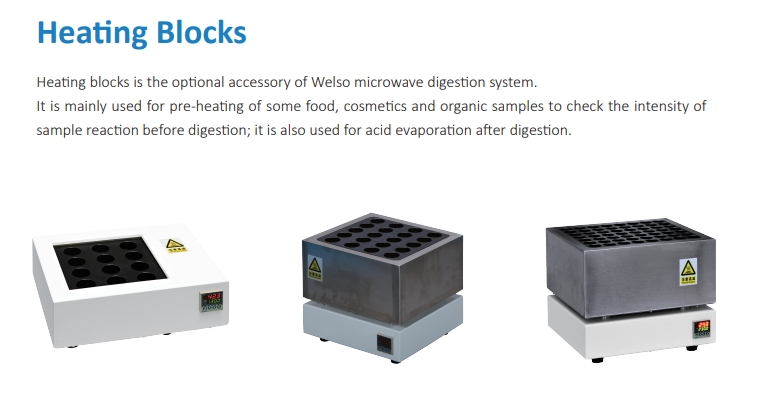

Rinse the cap into the vessel, and put inner vessels into heating blocks for evaporation. (Add glass beads if necessary and evaporate solution, don’t make it dry). Add another 5ml of hydrochloric acid solution and continue to heat until the solution becomes clear and colorless with white smoke (Figure 3).

Transfer the solution to a volumetric flask, rinse the vessel, merge the lotion solution into a 10ml volumetric flask, add 2.5ml of potassium ferricyanide solution (Note 4), set the volume with water, mix well and wait for testing.

Use atomic fluorescence spectrometry to analyze Selenium .Notes:

The sample needs to be grinded to fine powder (can pass through a 100 mesh sieve), and if the sample is suspended on the wall, rinse to the bottom of the vessel with digested solution.

If necessary, 10ml of nitric acid can be added first, and place in the heating blocks to heat up and remove the pressure gas. When the yellow-green smoke becomes light and white, take out the vessel and cool to room temperature, add the digested solution in proportion and slowly add hydrogen peroxide dropwise. The hydrogen peroxide solution will self-decompose at high temperatures: 2H2O2===2H2O+O2. Therefore, it cannot be added before placing it in heating blocks, and it needs to be added slowly after cooling to room temperature.

If the acid is not completely evaporated, the residual nitric acid in the sample will affect the selenium test results. When the concentration of nitric acid is lower than 15%, there is no significant deviation in the accuracy of the measured solution; When concentrations is above 15%, the accuracy of the measured solution deviates greatly as the acidity increases.

Potassium ferricyanide solution is used as a masking agent to form precipitation with metal elements such as Hg, Pb, Cu, As, Cd and other metal elements in the sample to eliminate interference. In addition, potassium ferricyanide aqueous solution can easily decompose into toxic substances when exposed to light, polluting the environment, and should be used as soon as possible [3].

Therefore, in most of the food digestion, when the temperature is raised to a certain temperature, the pressure in the closed reaction system will increase rapidly, in view of the existence of high temperature and high pressure in the reaction process, the power of microwave radiation must be controlled when the food sample is digested, and the equipment used needs to have multiple pressure protection measures to prevent danger.

Welso Microwave Digestion System Complete Protection Measures

Welso's microwave digester adopts 316L industrial-grade stainless steel chamber, explosion-proof design with multi-layer PFA coating for thermal insulation and corrosion resistance.

Non-contact all vessels fiber scanning pressure monitoring system to real-time monitor pressure of each vessel. And microwave output immediately stops once over-pressure to protect the digestion vessels.

Non-contact special IR temperature monitoring system of all vessels collects the temperature parameters at high frequency, and stops the microwave output immediately when the temperature in the vessels exceeds the preset parameters to protect the digestion vessel.

Meanwhile, it also monitors abnormal noises in the chamber to avoid risks. It has the function of instrument fault monitoring, and can diagnose various abnormal or faults timely and accurately to ensure the reliable operation of the instrument. It also has emergency stop function and the microwave will stop output immediately when the device is slapped and moved.

Besides application in food, microwave digestion systems are widely used in various fields such as environment, biology, medicine, cosmetics, etc., To ensure the normal and safe use of the instrument, Welso suggests everyone to know the operation process and safety precautions of the microwave digestion system.